In the digital printing era, where ultimate clarity and vivid colors are paramount, printers and large-scale printing equipment are undeniably at the core. However, these precision devices face constant threats from their natural enemies: dried ink, residual resin, and clogged nozzles, which compromise output quality and shorten equipment lifespan. Today, we will unveil a little-known component that plays a pivotal role in the maintenance of high-end equipment: 1,4-butanediol. It serves as the "cleaning guardian" safeguarding precision prints.

Why is printer cleaning so particular? **

Printers, especially inkjet printers, are not as simple as ordinary wiping. It faces three major challenges:

1. Precision: The nozzle aperture is as fine as a hair, and any solid residue or fiber may cause permanent blockage.

2. Compatibility: The cleaning agent must be able to strongly dissolve the ink, but it must not corrode the plastic, rubber seals, and metal circuits inside the equipment.

3. Volatility: After cleaning, it needs to be quickly dried without leaving water stains or streaks, so as not to affect the quality of the next print.

Traditional strong solvents (such as acetone, strong alcohol) have strong detergency, but they are also highly aggressive, which can easily lead to nozzle aging and pipeline brittleness. It can be described as "killing a thousand enemies but losing eight hundred of one's own.".

**Three Unique Secrets of 1,4-Butanediol**

It is under such strict requirements that the advantages of 1,4-butanediol are fully demonstrated.

Secret 1: Excellent ink solubility and mild chemical nature

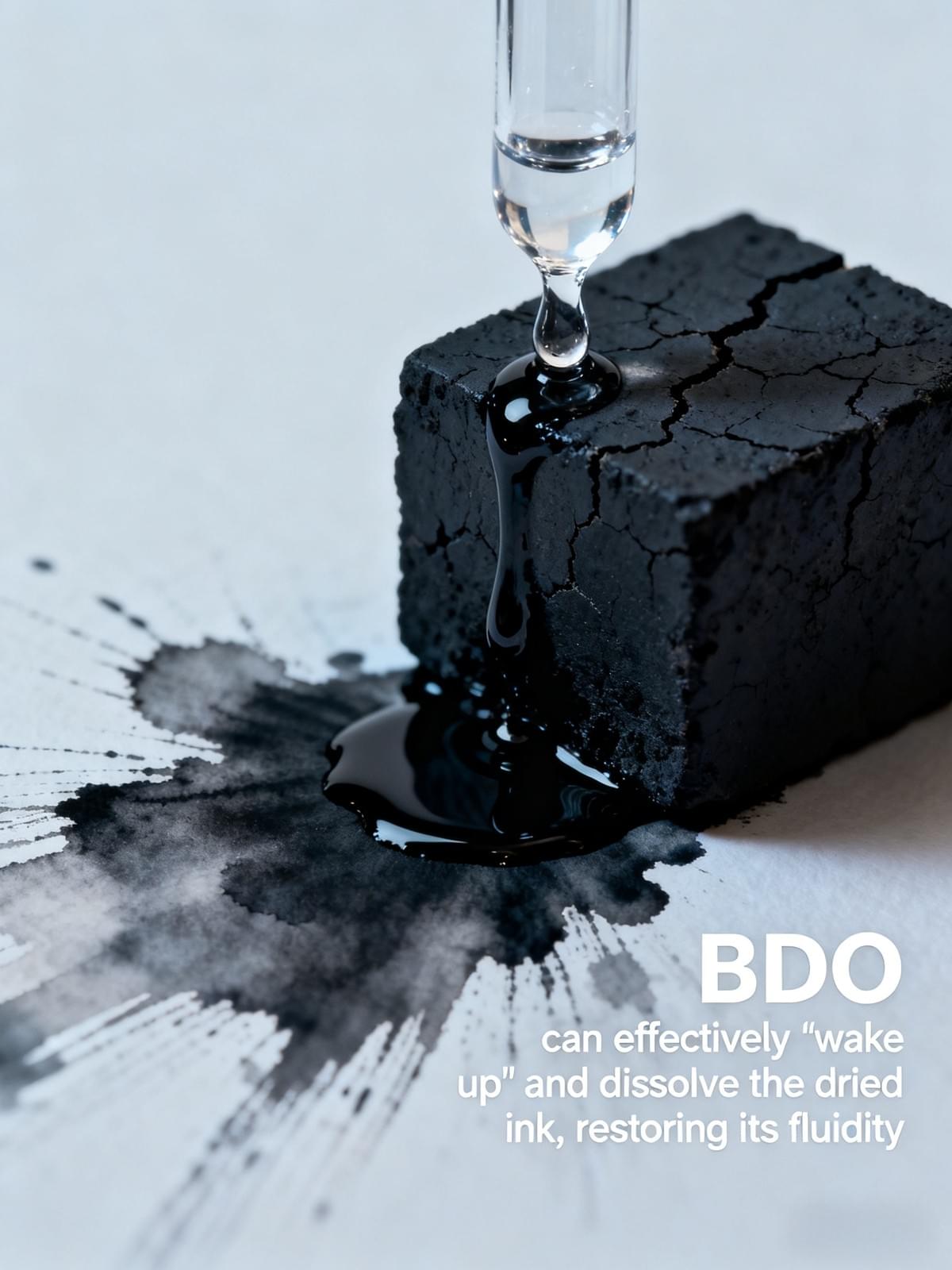

Principle: 1,4-Butanediol is an excellent solvent, which has good dissolving ability for water-based, dye-based and some pigment-based inks commonly used in inkjet printers. It can effectively penetrate and disintegrate dried and solidified ink particles, making them flow again and thus be easily removed.

Advantages: Most importantly, while exerting strong dissolving power, it has relatively mild chemical properties, making it friendly to various sensitive engineering plastics and rubber components inside the printer, avoiding equipment damage caused by cleaning itself.

Secret 2: Low volatility, achieving "traceless" cleaning

Principle: Compared to solvents like alcohol that evaporate quickly, 1,4-butanediol has a slower evaporation rate.

Advantages: This may sound like a disadvantage, but it is a huge advantage in precision cleaning. It gives the cleaning process enough time to fully dissolve the dirt without instantly drying on the nozzle surface and leaving half-dissolved impurities behind. Ultimately, it will evaporate evenly, leaving no streaks or residue, ensuring that the print head reaches its optimal state from the first use.

Secret 3: Absorb moisture and keep moist to prevent the nozzle from drying out

Principle: 1,4-butanediol has a certain degree of moisture absorption (moisturizing ability).

Advantages: In some professional printer cleaning and nozzle maintenance solutions, the addition of BDO can help form an extremely thin protective film on the nozzle surface. This slows down the rapid evaporation of ink moisture during standby, effectively preventing the nozzle from drying and clogging due to inactivity. It is particularly suitable for production environments where usage is infrequent.

Application scenarios: from daily maintenance to deep rescue

1. Special nozzle cleaning solution: It is the core component of high-end nozzle cleaning solution, used for daily automatic cleaning cycles or manual wiping to maintain the optimal state of the nozzle.

2. Curing ink soaking solution: For print heads that have been severely clogged, a special soaking solution based on BDO can be used to soften and dissolve them, achieving "resurrection".

3. Ink delivery pipeline cleaning agent: used to thoroughly flush the entire ink supply system to avoid color cross-contamination when changing ink colors or brands.

Future Outlook: Smart and Green Maintenance

With the advancement of Industry 4.0 and green manufacturing, the maintenance of printing equipment is evolving towards greater intelligence and environmental friendliness. Chemicals like 1,4-butanediol, which are efficient, safe, and biodegradable, perfectly align with this trend. Not only do they enhance maintenance efficiency and reduce equipment scrap rates, but they also minimize potential hazards to the environment and the health of operators.

Summary:

When your printer performs automatic cleaning next time, or when a technician performs deep maintenance for a large printing machine, please remember that it may be the unknown "cleaning guardian" of 1,4-butanediol that is guarding every nozzle that is thinner than a human hair, ensuring that every pixel can be accurately placed to present the most perfect image.

It proves through technology that true strength lies in both accurately solving problems and gently caring for equipment.